A Guide to Choosing the Best Fleet and Heavy-Duty Paints

As a fleet manager or trucking company owner, you know your vehicles are more than just a way to get from point A to point B. They are rolling billboards, critical assets, and a direct reflection of your company's professionalism. While you focus on engine performance, tire health, and driver safety, have you considered the crucial role of the paint job?

It’s not just about looking good.. it's about protecting your investment.

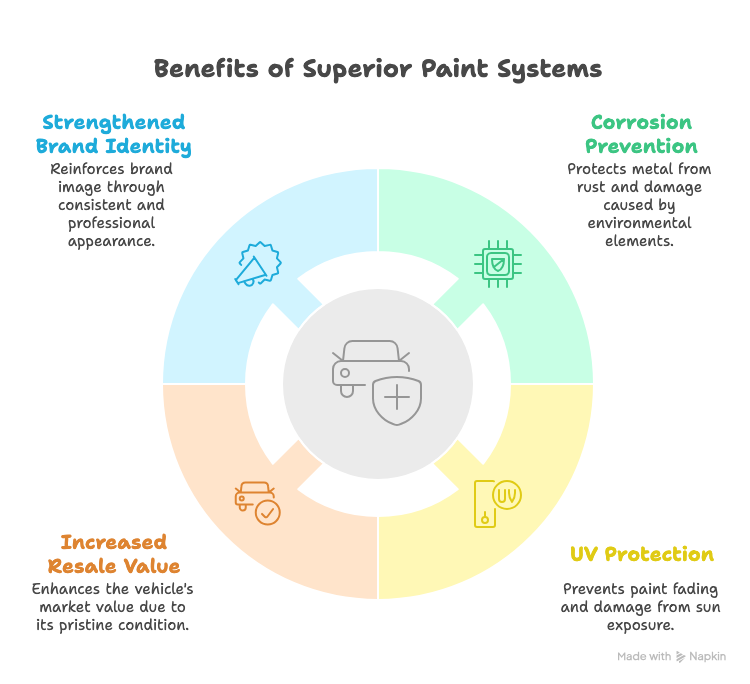

Choosing the right fleet and heavy-duty paints can be the difference between a truck that looks worn and rusted after a few years and one that proudly displays your brand for a decade. The right coating protects against weather, salt, road debris, and chemical exposure, saving you thousands in costly corrosion repairs down the line.

This guide will walk you through everything you need to know, from the different types of paint available to the key factors you should consider before making a decision. Let's dive in and ensure your fleet always puts its best face forward.

Why Quality Paint is a Non-Negotiable Asset

Think of a high-quality paint job as armor for your fleet. While a sharp, glossy finish certainly boosts curb appeal and brand recognition, the real value lies in its protective qualities. Your trucks, whether they're Class A tractor-trailers or smaller Class B box trucks, face a daily barrage of harsh conditions.

Industry Insight: "Your fleet is a rolling billboard for your brand. The quality of its appearance speaks volumes about your standards before your driver ever says a word."

The Heavy Hitters: Types of Fleet and Heavy-Duty Paints

Not all paints are created equal. The world of commercial vehicle coatings is specialized, with formulas designed to withstand extreme abuse. Understanding the main types will help you have an informed conversation with your auto body and paint shop.

Here are the most common options you'll encounter:

1. Polyurethane Coatings

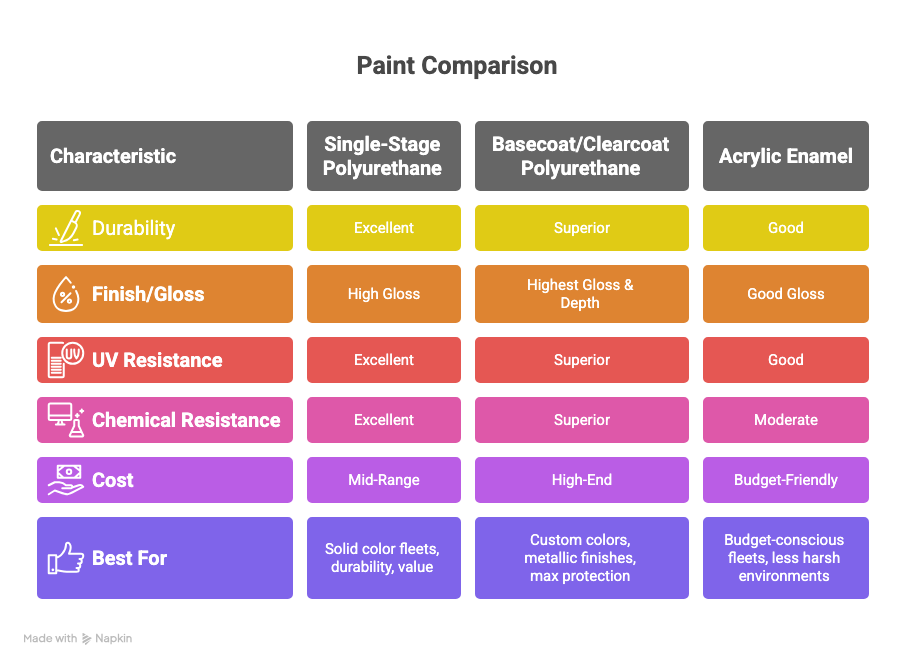

Polyurethane is the gold standard for fleet and heavy-duty paints. It's a two-part system known for its incredible durability, high-gloss finish, and resistance to chemicals, abrasion, and weathering. It comes in two main forms:

- Single-Stage Polyurethane: This system combines the base color and the protective clear coat into one application. It’s efficient and cost-effective, providing excellent durability and a beautiful finish. It’s a fantastic choice for solid-color fleets.

- Basecoat/Clearcoat Polyurethane: This is a two-step process. First, the color (basecoat) is applied, followed by a separate, highly durable clear coat. This system offers the best possible depth, gloss, and long-term protection, especially for metallic colors and complex graphics.

2. Acrylic Enamel

Acrylic enamel is another popular choice, often seen as a more budget-friendly alternative to polyurethane. It offers a good gloss finish and decent durability. While it may not have the same long-term resistance to chemicals and chipping as polyurethane, modern formulas have greatly improved its performance, making it a viable option for vehicles with a shorter service life or those operating in less harsh environments.

3. Epoxy Primers

While not a topcoat, no discussion about paint is complete without mentioning epoxy primers. This is the critical first layer applied to the bare metal. An epoxy primer provides a powerful foundation by chemically bonding to the surface, offering exceptional adhesion for the paint and creating a rock-solid barrier against moisture and corrosion. A quality paint job always starts with a quality primer.

Statistic Spotlight

According to AMPP (formerly NACE International), the global cost of corrosion is estimated to be $2.5 trillion USD. For the transportation sector, this means that investing in high-quality protective coatings like fleet and heavy-duty paints isn't an expense—it's a crucial strategy for asset preservation.

Key Factors in Choosing the Right Paint for Your Fleet

Now that you know the players, how do you choose the winner for your team? It comes down to balancing performance, appearance, and budget.

- Operating Environment: Where do your trucks run? A fleet in the salty, snowy Northeast needs maximum corrosion protection (like a polyurethane system), while a fleet in a dry, sunny climate like Arizona needs top-tier UV resistance.

- Vehicle Lifespan & Use: How long do you plan to keep the vehicle in service? For a long-term, front-line tractor-trailer, investing in a premium basecoat/clearcoat system pays dividends. For a shorter-term delivery van, a single-stage polyurethane or high-quality acrylic enamel might be more practical.

- Branding and Color: Do you use solid colors, or does your branding involve complex metallic or pearl finishes? Metallic colors absolutely require a basecoat/clearcoat system to look their best and last. For solid colors, a single-stage paint provides a fantastic, durable finish.

- Downtime and Budget: While a premium paint job has a higher upfront cost, it often leads to a lower total cost of ownership by reducing the need for touch-ups and repaints. Consider the cost of vehicle downtime during the painting process. A professional shop like FleetTech can provide an accurate timeline to help you plan.

- The Importance of a Professional Application: The best paint in the world will fail if not applied correctly. The process—from meticulous surface prep and sanding to expert priming and flawless application in a controlled environment—is just as important as the product itself. Whenchoosing an auto body shop, ask about their process, their paint booth, and the brands of paint they use.

Protecting Your New Paint Job

Once your fleet is looking sharp, you'll want to keep it that way. Proper maintenance is key to extending the life of the finish. Simple steps like regular washing to remove corrosive agents, occasional waxing to add a layer of protection, and prompt touch-ups of any chips or scratches can keep your paint job looking new for years. This care, combined with regular vehicle inspections, ensures your fleet remains a point of pride.

Frequently Asked Questions (FAQ)

Q: How long should a good heavy-duty paint job last?

A: With proper care, a high-quality polyurethane paint job applied by a professional shop can last anywhere from 7 to 10 years or even longer before showing significant signs of wear.

Q: Is it better to repaint or wrap a commercial truck?

A: Both have their pros and cons. Paint offers superior long-term durability and protection against corrosion. A vinyl wrap is excellent for complex, temporary graphics and can protect the underlying paint, but it typically has a shorter lifespan (3-5 years) and doesn't offer the same level of chemical or abrasion resistance.

Q: What's the biggest mistake fleet managers make with vehicle paint?

A: The most common mistake is choosing a provider based on the lowest price alone. A cheap paint job often means corners were cut on surface preparation or cheaper materials were used, leading to premature fading, peeling, and rusting. This ultimately costs more in the long run through repairs and repainting.

Give Your Fleet the Finish It Deserves

Your vehicles are a direct reflection of your company's commitment to excellence. Investing in premium fleet and heavy-duty paints is a strategic decision that protects your assets, strengthens your brand, and delivers a powerful return on investment. Don't settle for a finish that just gets by; choose one that stands out and stands up to the demands of the road.

Ready to transform your fleet with a durable, professional finish?

The expert technicians at Fleet Tech's Auto Body & Paint Shop are here to help. We use state-of-the-art equipment and premium coatings to ensure your vehicles look their best and are protected for the long haul.

Contact us today for a free consultation and let's discuss how we can elevate your fleet's appearance and durability.